How do synthetic and natural fibers compare in composition,

properties, natural resource use, and impact on society?

Prep: 1-2 hr

Activity: 4-6.5 hr

6-8 Middle School

Students begin this activity by using a set of guiding questions to research the source, processing requirements, and final properties of natural and synthetic and fibers. After the research is complete, students investigate properties such as absorbency, stretch, shrinkage, and ability to take a dye of at least one natural and synthetic fiber. Natural fibers for research include cotton, linen, silk, and wool; synthetic fibers include polyester, rayon, spandex, and acrylic. Students are also asked to survey their own clothes and record and tally the fiber content of what they wear.

A definitive test for separating synthetic and natural fabrics is the burn test. How the fabric responds to the heat of a flame, the color of smoke produced, the odor, and properties of the ash or residue remaining identifies the base unit of the fabric—cellulose, protein, or a manmade monomer. Make observations from the burn test demonstration your teacher performs or watch the 4-minute video “Textile Fibers Burning Test” with numerous examples.

What are your observations?

How do synthetic and natural fibers compare in composition, properties, natural resource use, and impact on society?

PE MS-PS1-3. Gather and make sense of information to describe that synthetic materials come from natural resources and impact society.

Obtaining, Evaluating, and Communicating Information

PS1.A: Structure and Properties of Matter

PS1.B: Chemical Reactions

Structure and Function

Teacher Demonstration

(Optional)

Student Investigation

(Per group or individual)

Food coloring will stain your hands and clothing so keep your work space clean and clear. Hair dryers or heat lamps can burn your skin if exposed for too long. Safety Gloves and Safety Goggles are required.

For the fabric burn test demonstration, gather a 2 cm × 8 cm sample of cotton or silk and polyester or spandex; a votive type candle; matches; tongs or long tweezers; and an aluminum pie pan or large square of aluminum foil.

Student Research

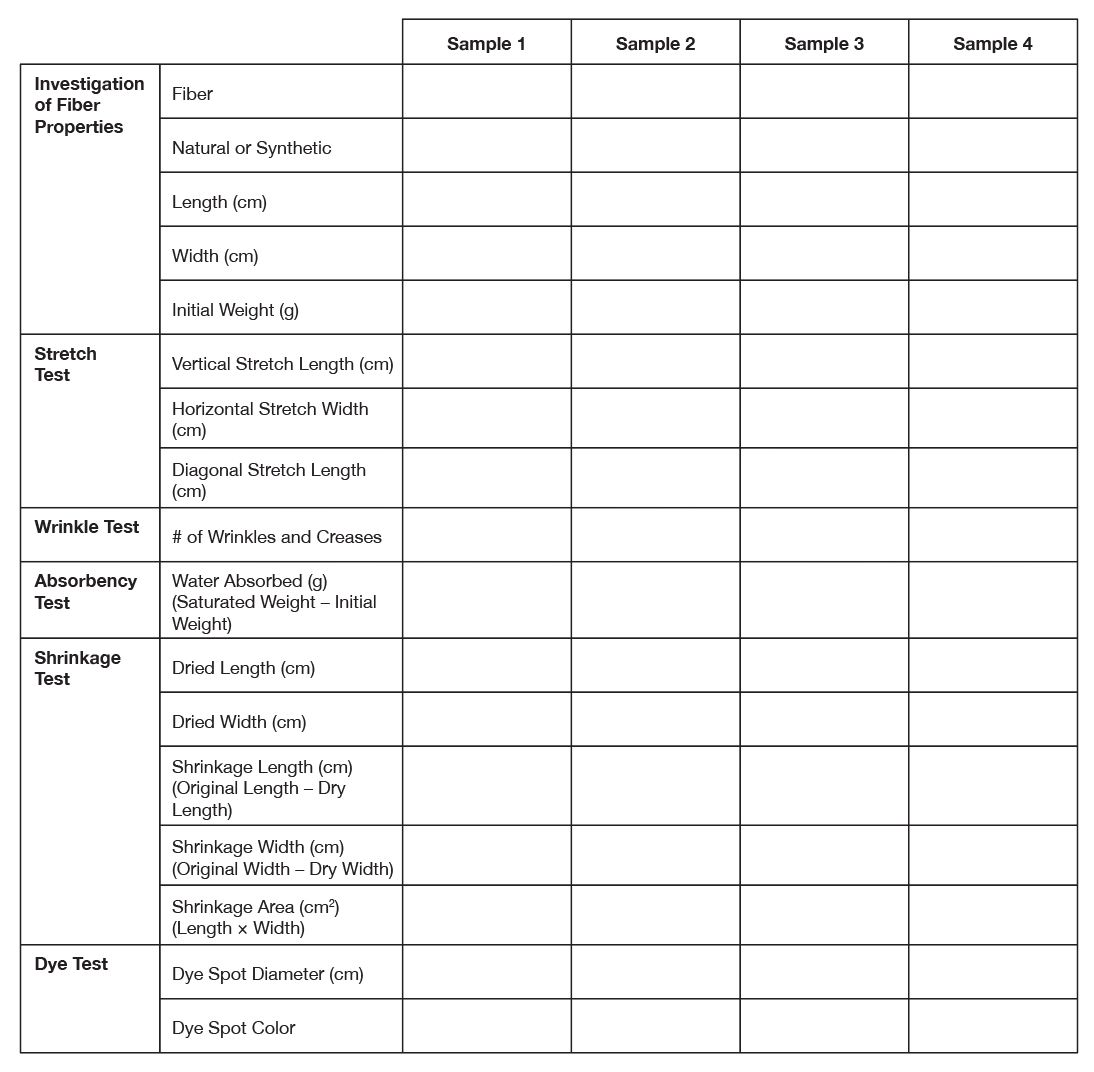

Investigation of Fiber Properties

Stretch Test

Wrinkle Test

Absorbency Test

Shrinkage Test

Dye Test

Student answers will vary.

Add your data to a class data table.

Make an online, paper, or white board class data table for each individual or group to share answers. If fabric samples are repeated, those values should be averaged.

Summarize the properties of natural and synthetic fibers.

Natural fibers tend to wrinkle more, be more absorbent, shrink, and take more vivid dyes. Synthetic fibers wrinkle less, are less absorbent, don’t shrink, and can be hard to dye. If you completed the burn test, natural fibers produce ash, while synthetic fibers melt. Rayon is the exception since it is made of processed cellulose.

How does the manufacturing and processing of fibers and fabrics impact natural resources and society?

All the fibers and fabrics require natural resources. Natural fibers tend to come from renewable resources, while many of the synthetic fibers and fabrics require petroleum, a non-renewable resource. Most natural fibers will biodegrade faster than most synthetic fibers.

How did your investigation results compare to your research findings?

Lab data should support research findings.

Introduce forensic fiber identification techniques by challenging your students to identify an unknown fiber with this fiber identification kit!

We are committed to providing the lab kits, instructional materials, and often free activities and supporting digital resources that do as much heavy lifting for you as we can.

*Next Generation Science Standards® is a registered trademark of Achieve. Neither Achieve nor the lead states and partners that developed the Next Generation Science Standards were involved in the production of this product, and do not endorse it.

Get the latest news, free activities, teacher tips, product info, and more delivered to your inbox.

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyse our traffic. By clicking "Got It", you consent to our use of cookies. Privacy Policy